Do you want something better than this in your closets and hallways? You must, as a matter of safety and compliance with building codes, even though your hardware store may sell only the bare bulbs and cheapest porcelain fixtures.

For much of 2017, your choice as an Amazon shopper might have been 4" GetInLight .

An eternal hallway night light:

This 4" GetInLight draws 9 watts to produce 550 lumens, double the downward illumination from a 60 watt incandescent dimbulb. Adjusted to equal illumination, the bug-proofed GetInLight draws 4.5 watts, a reduction of more than 90%. That is nearly the full savings that is achievable with LED lighting, easily available now. This will shine on for at least thirty years with no need of maintenance, if AC Driver On Board lights are as durable as external converters of DC LEDs. Here over a guest bedroom door as a night light, the achievement is safety. There was no light here before.

On a bug-proofed RACO 175 junction box, 4" GetInLight draws up to gasketed sealing, via an awkward adapter ring. GetInLight has been a worthwhile nuisance, for lack of the adapter plate now included with a nearly identical 4" Westgate LED. Exactly identical boxes are the clearest indication GetInLight and Westgate are made in the same China factory. Amazon is the actual importer. Westgate and InLightMotion don't manufacture anything.

As an Amazon shopper in December 2017, you will find the Westgate now reviewed here, a better light and a better deal than the slimmer, more sleek GetInLight still offered at Amazon:

Westgate 9W 4" Dimmable Disk LED Surface Mount Disc Downlight Kit Accessories Included - Spun Aluminum Housing - Energy Star Rated - 550-600 Lumens 120V (1, 3000K Soft White)

Your cost: about $14. Go for it. With the Seoul Semiconductor Driver On Board, it will readily mount to any ceiling junction box, however overloaded with wiring and however unsafe from overheating of wires by those 100 watt or bigger bulbs you can't buy anymore. You want more light. You want safety. You want to do your part saving energy and money.

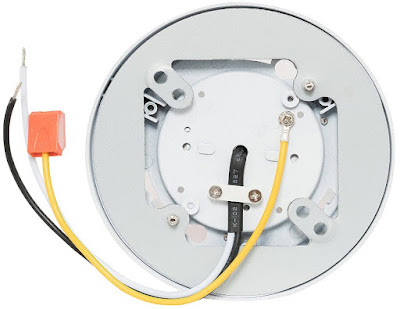

Here see the important box adapter plate that Amazon fails to ship, with GetInLight. See the very many paths that glow brightly within a can light or junction box, impossible of sealing. A bug entering the junction box will certainly die upon the luminaire lens, seeking and never finding, the heaven of diode contact. This is my typical installation on a sealed-bug-proof RACO 175 steel junction box. The deep RACO 175 boxes have been necessary for LED disk downlights with a bulky external driver from house AC power. See that even with the adaptable and rugged RACO 175, caulking is needed to keep bugs out.

Please find my positive review of this light as a Google Photos Album . Know right away that you must do better than the simple adoption suggested so far. Wiring with decrepit electrical insulation must be replaced. If your junction box is old and leaky or if you stuff this into a 4" can light, you will be happy, for awhile. Then you will see the lens darken from litter of dead bugs. LED lights do attract bugs, especially where seen from the ceiling interior as bright points, the stars that denote vertical wrongly and then madden.

Get used to LED disk downlighting. It doesn't look like your bulb, but it lasts forever, and saves more than 90% in operating cost versus point-source incandescent. Few of us have tried these, but they are our illumination of the future. We quickly see them as beautiful, and that will be especially true of the shapely little Westgate light

The Westgate-included adapter plate at the back side is released from the luminaire assembly and becomes part of the ceiling interface. Keyways in the luminaire are at 2 3/4" pitch, and the adapter plate reaches out to 3 1/2" pitch more-commonly found.

Now consider Westgate luminance (glare) numbers. Diode luminance and array luminance are both small compared to a glaring light like Nicor DLS4.

Assess brightness of the Westgate LED, comparative task illumination at my comparison stand. During evaluation of an EiKO LED edge-light, compare several LED luminaires stage left, against a 100 watt point-source incandescent bulb at stage right. The point source bulb is that still legally sold, Philips EcoVantage 1490 lumens, 72 watts. Choose LED luminaires of 3000° color temperature with large beam angle typically 120°.

4" Glimpse of 2013, called 450 lumens, at left. Philips EcoVantage "100 watt" bulb at right. I have made this comparison many times, always finding equal brightness and slight difference of color temperature with bulb nearer 2700°K. I call both "B4", by definition. This is the brightness by which very many homes with 8-foot ceilings have set luminaire spacing. B4, about 500 lumens, will be the goal in usual LED swaps for closets, narrow hallways and small bathrooms. In larger rooms with want of productive activity, we will want more than B4 in swaps upon existing junction boxes. More light is good.

The luminaire at left in this photo is Westgate 4". The Westgate is only a bit brighter. I have found in very many comparisons that a "100 watt" bulb gives task illumination comparable to a LED disk of about 500 lumens with about 120° beam angle. Question that the Westgate is 600 lumens.

Now Westgate 4" LED called 600 lumens is at stage left. Eiko called 650 lumens on its box front is at right. The Eiko is identified as 800 lumens in its Lighting Facts label.

This is a high-end new home. Yet, the access to the attic is standard cheapness and thoughtlessness. The plunker and tied-on R38 batt lift with difficulty and danger. Slight handling errors break the brittle drywall. Allowing for bare areas, the effective value of the burdensome insulation is less than R7.

75% R38. 25% uninsulated.

1/(Reff + 3) = .25/3 + .75/41

Reff = 7

Or, is it even that good? The number 3 in math so far, represents the sum of convection and conduction resistances in a complex wall with at least two convection interfaces, aiming for a highest number, so as to not over-estimate savings with correction. What if the real sum here is only 1.3?

0.17 + 0.45 + 0.68 = 1.3 (Colorado Energy numbers)

1/(Reff + 1.3) = .25/1.3 + .75/(38 + 1.3)

Reff = 3.4, doubling the heat cost as-found. Ueff = Reff = 1/3.4 = 0.29

My insulation math at 95% furnace efficiency and natural gas cost of $2 per therm, says heat cost per year is: $2.4*Area*.88/.95*Ueff.

Area = 3.6 sq ft.

Cost per year: $2.30. Compare to cost of $0.20 per year at 3.6 sq ft of R38 ceiling, U = 1/39.3.

With my usual analysis with that number 3, Reff = 7, cost per year is:

$2.4*3.6*.88/.95/(7 + 3) = $0.80.

Save $2.10 per year or $1.50 per year with the better hatch cover. Motivation is the same whatever the math. The gob is even more a nuisance and safety hazard, than a false economy. Avoid spending more for the better hatch.

Here is the replacement hatch cover, ready for application of facing drywall. An R19 unfaced batt was at hand, costs less than R15 and is acceptable where it overfills the space.

Here is the completed useful attic with the new hatch cover stowed upon a tray.

I intended to use the 1x4 wood frame in the ceiling as-found. Finding that frame unacceptably out-of-square, a repair was instructive The RHS member of the frame was long by 7/16". In the correction by steel-cutting Sawzall, a steel edge frame for drywall was confirmed. The drywall and steel edging formed into the hole reduced possible opening size by more than an inch.

I think this is a much better arrangement of a generally-useful hatch, allowing maximum hole size with 24" framing on-center tolerance of plus or minus 1/2". It will be better that the hatch and its frame are built with precision as a matched set. I think of ways to increase durability while reducing cost.

Show a larger opening where the hatch assembly is installed with least effort, into a simple drywall cut. Show wood veneer banding of the cover drywall edges as thought to reduce cost and improve ruggedness. A high-end cabinet shop finding fill-in work and uses of scrap material, making thousands per year, will find many opportunities of improvement and lowered cost. Energy Trust Of Oregon, and Oregon HBA: Please support this, including better content of IECC Residential Chapter 4, paragraph R402.2.4 at 2019 cycle, timely with showing at 2019 International Builders Show in Las Vegas. Showing would enlist cabinet makers anywhere, at minor cost for the advocacy. Any shop could make improvements, to be shared.

Flexible grout completes the ceiling drywall edge over the hatch frame, with texture match. Think to offer a white melamine plywood facing instead of heavy drywall. In practice, a manufactured hatch of standard size will cost less than drywaller steel-edging of a plunker hole while complying with raised energy-efficiency code requirements.

I do many important things in an attic, and work hard to share with others. In this home, I completed a better example of R30 insulation hard-covering a skylight . Most important to the home owner, I created a useful attic, vastly capable of storage, enabling rental of the ground floor of a grand year-old duplex home. Found conditions were dark and dangerous. Access anywhere was blocked by hanging HVAC ducts. A full report upon the HVAC demolition and replacement is out of place in this blog post, and will be relocated after the ruined new-home furnace is replaced, hopefully in Spring 2018. Place some content now, to be moved to an appropriate post

All HVAC ducts are suspended. This is common, but it is not good practice.

Dangerous passage around the poorly-insulated skylight had trampled floor insulation value.

No passage this way, around the awful furnace installation. See that the furnace is ruined by absence of filtering provision. An entire side of the furnace was hacked open for absurd return-air ducting. The furnace inlet ducting must be modified to provide filtering of the return air.

Awful conditions were found in the demolished furnace-outlet D-box. Read more and see more in the associated photo album .

See the improved furnace proud upon a smooth attic floor, in photos at the beginning of this post.

Here is an as-found view of a new-home attic in Portland, Oregon. Standing atop the usual OSB rim about a hallway ceiling drywall-plunker-access, all is booby-trapped against usefulness. Pulled-up HVAC and fan ducts are in the way, obstructively kinked, everywhere. An adventure has begun, to make the huge attic useful. This post addresses repair of a ten-ft tall bathroom skylight with defective insulation, seen in this view. A full set of captioned photos of the process is consulted.

I imagine a City Of Portland building official inspected and approved the insulation in this home, relying upon 2009 International Energy Conservation Code in effect as the 2014 Oregon Energy Efficiency Specialty Code . See that such code is not accessible despite intentions; there is nothing at followed links. My 2015 IECC book at the Index, Skylights, calls out: R303.1.3 (U-values for glazing), R402.1.2 (skylight U-factor of 0.55, wood frame wall R20), R402.3 (words about fenestration, n/a walls),Table R405.5.2 (1)(standard reference design specifications, for skylights: None.). Defined: R202 (Glass or other transparent or translucent glazing material installed at a slope of less than 60 degrees from horizontal.)

An inspector might have looked for and found R20 at the skylight walls, but I will show that that is only wishful thinking. Find better requirements a Portland, Oregon insulation installer would have been required to follow, under better supervision of Specifications of Energy Trust of Oregon. These say:

skylight—Any window unit in an opening in the roof assembly, including one that is installed at a slope of 15 degrees from vertical or greater.

AT 1.13—Vertical Walls in Attic Spaces

Any vertical wall in an attic that separates conditioned space from unconditioned space shall be sealed for air leaks and shall be insulated to fill the cavity. Insulation shall be secured and covered with a vapor-permeable air barrier. Vertical walls may include side walls of vaults, skylights, transitions in ceiling height or other surfaces. See AT 2.6 for program requirements for knee wall insulation.

AT 2.6:

Knee walls shall be sealed for air leaks and shall be insulated and covered with a vapor-permeable air barrier.

Rebate Rules:

R-15 for 2x4 cavities; R21 for 2x6 cavities; cover attic side with vapor permeable air barrier.

Where this skylight has some 2x6 boards, R21 might be commanded. It isn't clear.

I persist in challenging that attic walls may be as thick as one wishes, unlike exterior walls. Better rules will deal with confusions including so much on-flat framing at a skylight. Where attic walls are extremely challenged by Summer heat, they should be insulated much better than exterior walls. I insulate attic walls to modest R25 (with R30 batts 7.5" thickness and with lessened framing thermal shorts). The vapor-permeable air barrier specified, can't be simpler than a thorough covering of good 3/8" plywood. I offer well-practiced means of attaching the plywood covering.

R21 was not achieved here.

Here is my math for the skylight with insulation merely draped over on-flat 2x4s of the trusses:

Say total inside area of skylight drywall is 100 sq ft. Skylight insulation is in contact with drywall only at end walls, 25 sq ft called R21. On side walls insulation has full effect only where draped over on-flat 2x4s, effectively R21 over 11 sq ft. Remaining area, 64 sq ft, has no insulation filling cavities, and at worst has no value.

100/(Reff + 3) = 25/24 + 11/24 + 64/3; Reff = 1.4 for the entire 100 sq ft area.

My insulation math at 95% furnace efficiency and natural gas cost of $2 per therm, says heat cost per year is: $2.4*100*.88/.95*(1/(Reff + 3)).

The penalty with loose draping, or any draping, is large. Draped insulation must not be allowed.

Accepting that draped batts do resist heat convection, allow Reff = 7, for payback math, vs. better insulation to be demanded and to be achieved. I believe that is a sufficiently large number to avoid over-estimate of weatherization savings. As in the title of this post, accuse that better than Reff = 1.4, can not be demonstrated. Energy savings at skylights is relatively easy, and comes with better safety too. An outside air barrier is required and is nicely provided in 3/8” plywood hard covering. 7/16" OSB saves some money, but scrap must be disposed as trash. In some homes the hard covering of a skylight prevents a deadly fall in an attic tumble against shaft drywall. Where one wants a useful attic and may not use a respirator, a nearly-complete covering of insulation is appreciated. Where my allocated cost of the skylight covered insulation is between $300 and $500, and savings are $15 or more, estimate an acceptable less-than-twenty years recovery of cost.

Mostly, be grateful for better summertime comfort, perhaps continuing to avoid the need and cost of air conditioning.

Pull the nice but useless Certainteed R21 kraft-faced batts from the skylight side walls. Build simple wall extensions of 3/8" plywood cuts 7 1/4" wide that efficiently consume 96" panel length, and stitch them to the 1 1/2" truss depth wherever they fit and align with 2x2 nailer positions, that will support hard siding of 3/8" plywood. In the truss rows, add 2x4's to increase depth for added end wall insulation. Ensure that the plywood cuts forming top and side constraints of the side wall insulation, are very nearly air tight.

Use new Certainteed R13 unfaced batts 15"x96", accurately cut, to cover skylight drywall. Stuff through the floor gaps, completing R60 insulation about the skylight below the floor that is up 21.6" from the attic drywall floor. Where the skylight peak is nearly 10 ft tall, be grateful for the elevation boost of the higher attic floor of 5/8" plywood. A stool for added reach is safely used upon a flat and complete attic floor.

The found R21 batts are stripped of their ripped and crumpled kraft facing, and nearly complete the R30 insulation fill, now easily cut to fit.

Use insulation scraps to fill in low spots of the R30 insulation.

The 3/8" plywood side panels were cut to fit, before the insulation was placed. See that R30 insulation is complete and pillows to greater than the 7.5" thickness defined by 2x2 nailers. See thorough already-completed R30 end wall insulation.

See progress cutting the next skylight face plywood. This end of the now-floored attic is a quite nice, brightly-lit wood shop, for now. I love my Milwaukee saw with laser light well suited to my right-handedness. All sawdust and wood scrap will be recycled as bark mulch. Then don't use less-expensive OSB that must be disposed as trash.

Pre-fit the second skylight face, set with screws.

See 2x6 uprights tied into the truss planes at this end of the skylight. With 2x4 nailers now secured to the side walls, I may release end wall plywood facing to trim the 2x6.

Skylight finished now. The brightly-lighted attic is the best place to do brush-on paint coats of the R15 access cover.

Where Energy Trust Of Oregon chooses to do nothing upon notice of this post, I have edited post Labels to include "Voids Under Attic Insulation." Emphasize then that voids behind some insulation are more sure of being energy hogs, than voids under insulation. The energy dissipation is in convection, air flow past an energetic surface, at temperature different from ambient. Smooth skylight drywall is a superior energy convector of air in motion through gaps. Gaps are made worse where out-of-contact insulation has smooth or deformed facing. The situation is surely better than worst case R2 average, but may not be better than R7. There is no basis for treating insulation as fully effective. There clearly is not compliance with Energy Trust Specifications, in loosely-written new-home building code. Energy Trust calls for treatment of a skylght shaft, R15 insulation, same as for 2x4 exterior walls. New-home building code does not mention skylights. Look in the 2015 IECC code table below to see that a new home skylight in Zone 4 should have insulation of 2x6 construction. In fact, non-specific instructions, are ignored.