All I could discover in the two days is within the water circle at center, this map URL .

Twelve hours past arrival, rested and oriented, I pursued a very active day within museum hours of about 10am to 5pm. Take a ten minute train ride from Central Station to Østerbro Station. Walk about Kastellet, and arrive at The Little Mermaid by 9am, This map URL

Continue about Kastellet, to Gefion Fountain, a bronze fountain completed in 1908, depicting Norse goddess Gefion plowing the sea with four oxen.. Admire the opal-hued clean water.

I didn't cross any of the bridges to the central island of Kastellet.

Soon at my left I passed Churchillparken , in part with a fence guarding a construction zone.

Learn this bit of history in tribute to Danish resistance of German occupation 1940 to 1945 :

The exhibition of The Museum of Danish Resistance remains closed due to a fire on April 28, 2013. The damage was so extensive that the building had to be demolished.

All museum objects and archives were saved. The damage was to the building only.

A new exhibition building will rise on the same spot. This new building is expected to be completed in Spring 2020.

See Rockwool stone wool batts placed as opportunity arises, to tight fill of the structure annulus.

This is a fast-moving scene of cylindrical brick-laying, with progressive insertion of mineral wool batts perhaps foot square, four feet long.

Rockwool Murbatts. What are they?

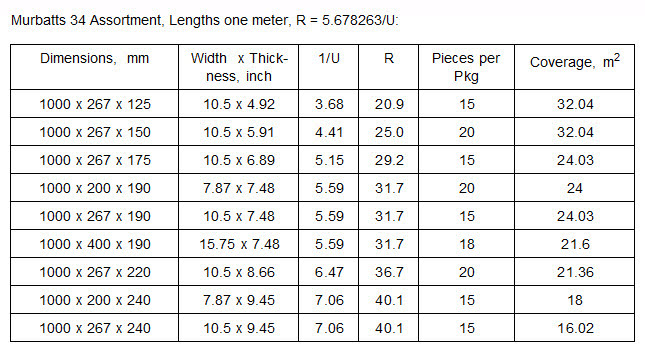

Murbatts are offered as Murbatts 32,34 and 37, where numbers are product thermal conductivity in units mW/m°K.

Here is an image of the Murbatts 37 datasheet, in English translation.

The many shapes and thicknesses offered are important for a spectrum of real-world insulation needs. Qualities wanted in the insulation of the building walls annulus include consistent dimensions and toughness in handling.

.

Translation from modern metric conversation, is first in dealing with units of measurement. I must convert my math and understanding of USA standards, to Danish practice with metric units. In the table above, for product Murbatts 34, see that thickness 150 mm (5.9 inch), has European 1/U = 5.51, and U = 0.18. Compare to required U of a wall, low value 0.2 or high value 0.4, in this EURIMA table.

https://www.eurima.org/u-values-in-europe/ I imagine the annulus in the photo is at least 150 mm. More likely, I think, 190 mm, 7.5", similar to the R30 thickest batts sold in USA.

Please study the presentation of Rockwool insulating value with this table for Flexibatts-37 and -34, for consistency with my USA Insulation Math and with method of conversion between USA R-value, and European U-value..

The units of European U-value are m²°K/W.

There are many fine details of European employment of Rockwool batts, needing instructive comparison to present USA home construction. Here is a cathedral ceiling.

Rockwool Poland documents some thoroughly-planned and intricate batt super-insulation, in this YouTube video with 1.7 million views.

https://www.youtube.com/watch?v=0OBdfQngh_M

From the Rockwool North America factory in Milton Ontario, or perhaps in Grand Forks British Columbia, I find a pretty-good spectrum of batt choices. These batt types and thicknesses are stocked by IDI, my insulation supplier in Tigard, Oregon. Pricing for me is included to show that Rockwool batts are less expensive than inferior fiberglass batts.

I think it is proper to compare insulation value as proportional to volume fully filled at claimed R-value, and with that volume reduced where observed batt thickness, is less than the space claimed to be filled. The minimum discounting of value is with wrong presumption that thinness alone is a problem. In fact, thin batts may have no value at all if outside air is free to circulate around and through the batt. Where a Rockwool batt claimed 3.5" is in fact 3.3", reduce batt volume by times 0.94. Where a fiberglass batt for a 3.5" space is only 3.0" thickness, reduce batt volume by times 0.86.

Look then at my year-2019 pricing at IDI, for fiberglass batts. Any manufacturer of fiberglass batts may be assumed, where manufacturers have colluded together to match and raise prices.

R19 kraft-faced $0.64 per sf

R23 kraft-faced $1.50 per sf

R15 unfaced $0.98 per sf

Bump these fiberglass prices up vs. Rockwool, by thinness ratio, 0.94/0.86, times 1.09. And know this is far too-fair to the fiberglass. Fiberglass batts allow far more air circulation through them and around ill-fitting edges. Kraft facing, usually without smart use of stapling tabs and with kraft crumpling, is disastrous to insulation value. Apply just the multiplier times 1.09.

At R15, fiberglass batts cost more by the ratio 1.09*0.98/0.75 = Times 1.42. Even the best fiberglass batts, R15, cost 42% more than Rockwool, or worse. Ordinary fiberglass batts may have no value at all.

Look back at sample prices I have paid for R15 unfaced fiberglass batts;

May, 2009 $20.61 for 67.81 sf, $0.30 per sf, $0.02 per R per sf

August, 2013 $20.61 for 67.81 sf, $0.30 per sf $0.02 per R per sf

June, 2014 $50.62 for 77.5 sf, $0.65 per sf $0.043 per R per sf

July, 2016 $58.24 for 112 sf, $0.52 per sf $0.05 per R per sf

April, 2018 $77.97 for 104 sf, $0.75 per sf $0.05 per R per sf

July, 2019, the not-exercised offer at $0.98 per sf. $0.065 per R per sf

I stopped buying fiberglass batts in 2018, equally because of poor thickness, and because of the accelerating cost. Who do fiberglass manufacturers think they are fooling? And where Owens Corning and Johns Manville offer decent mineral wool batts at Home Depot and Lowe's. know thickness and width offerings are very limited. Where Owens Corning offers smaller bags of ThermaFiber mineral wool, $13.93 for a 24.5 sf bag of R15-15 in July 2018, they do not capitalize on the excellent handling advantages and better pricing ($0.57 per sf vs. Rockwool $0.75). Other sizes, as for 24" framing, are not offered at either Home Depot, or Lowe's.

Hurrah, Rockwool!

I wish for reason to return to Copenhagen.

Copenhill, Copenhagen, Denmark

From afar Copenhill looks like a typical industrial plant with smoke billowing from its chimney. Get closer and you’ll spot adventurists traveling up and down the sloping roof of this shiny, metal-clad structure — and soon realize that Copenhill is an innovative and futuristic recreational park. There’s opportunities to ski, snowboard, sled, and hike. It’s even possible to scale the outside via the world’s highest climbing wall. All of this activity occurs on top of a waste-to-energy plant that helps to power thousands of city homes — part of a mission to turn Copenhagen into a carbon-neutral capital, and to offer alpine sports in a mountainless country.

No comments:

Post a Comment