Out of necessity for a customer, I have gained lessons in the usefulness of UltraTouch cotton batts in residential weatherization. Here is a sharing of those lessons.

The owner of the reported home aimed to be best green, in needful improvement of insulation, in Fall, 2008. Then, and now, UltraTouch denim batts by Bonded Logic, Inc., offers

impressive claims.

UltraTouch™ Denim Insulation is the successful combination of 35 years of insulation experience and a revolutionary patented manufacturing process that has created a superior and safe product.

UltraTouch is made from high-quality natural fibers. These fibers contain inherent qualities that provide for extremely effective sound absorption and maximum thermal performance. UltraTouch has No Fiberglass Itch and is easy to handle and work with. UltraTouch contains no chemical irritants and requires no warning labels compared to other traditional products. There are no VOC concerns when using UltraTouch, as it is safe for you and the environment.

UltraTouch is also a Class-A Building Product and meets the highest ASTM testing standards for fire and smoke ratings, fungi resistance and corrosiveness. UltraTouch™ Denim Insulation contains 80% post-consumer recycled natural fibers making it an ideal choice for anyone looking to use a high quality sustainable building material.

UltraTouch makes installation user-friendly. The inclusion of perforated batts allows for quick and easy off-size cavity installation. Simply measure, tear, fit and you're done!.

Many bags of UltraTouch R30 in size 23"x48" were purchased, for placement in the crawl space, by a hired top-notch weatherization contractor, and for the attic, to be placed by the home owner. Things did not go well, with more than $8000 paid to the contractor, and more money tied up in mis-applied or stockpiled cotton batts, by the home owner. All for little, if any, saving of energy. The home owner was responsible for misunderstanding how to insulate an attic, but was misled by the bad example of the contractor's work in the crawl space, and couldn't find guidance anywhere.

In reporting here, I intend to be useful to contractors and their management authorities everywhere. I hope to also get the attention of batt manufacturer Bonded Logic, Inc.. Bonded Logic may not sell product with no responsibility to advise in competent usage. From an experience here, consumers should learn that benefit from cotton batts is not easily obtained. There are many ways to use them inappropriately. Cotton batts are not uniquely "green;" in that deserving slack over misuse. Search, that now readily finds this blog post, nets little other help, and finds a lot of condemnation. Cotton batts are useless placed alone as wall insulation, where they can't adjustably fill cavities, and cavities not full may have no effective insulation. The recently-added Bonded Logic brag of perforated batts is empty. Batts still will not fill a wall on thickness, and perforations will likely be at unlucky widths.

Here, I find pretty decent usage of cotton batts in an attic floor as top layer with flexible fill-in of fiberglass, liking that they tolerate being walked upon. In a crawl space, after a lot of work, I guess they are ok.

Photos that follow are drawn from a Web album with similar captions:

Repairing The Installation Of Cotton Insulation Batts In An Attic and In A Crawl Space

The attic treatment of cotton batts began with taking down batts unwisely hung from roof joists. After a couple of years, mold was starting to grow above the batts, at the underside of the roof sheathing. Batts were wet.

Cotton batts dropped from roof joists and brought up new, would cover about three quarters of the attic floor.

Top up an R21 insulation base layer using new R11 batts. Supplement R30 cotton batts crossing floor joists, with R30 fiberglass batts. Protect all soffit vents with plywood baffles, and place R30 all the way out to cover exterior wall headers.

Note a Romex electrical wire here, correctly running over, not through floor joists. With thick insulation, electrical service should be permitted by simply lifting top-course batts.

Plywood decking is very important to work access. Plywood is raised 5" above floor joists, upon new 2x4 uprights 24" oc.

Furnace return air ducts are covered with R21 insulation, minimum, including a firm skin of poly skrim kraft upon R11 basement wall insulation. Duct insulation is tucked into top layer batts, or is screwed to plywood decking.

With the blocked access, the home owner was concerned about the placement of the crawl space batts. The batt installer, after days of awful work in this, would not be confronted. Thinking things weren't right, the home owner chose to forego a rebate claim, and didn't know what to do for resolution.

In the course of attic work, I inspected the crawl space. I reported that, as expected, the twined-up batts were sagging everywhere, only in contact with flooring in lines at edges. Full floor contact is mandated by regulating authority, Energy Trust of Oregon, ETO. Their rule stated:

In the course of attic work, I inspected the crawl space. I reported that, as expected, the twined-up batts were sagging everywhere, only in contact with flooring in lines at edges. Full floor contact is mandated by regulating authority, Energy Trust of Oregon, ETO. Their rule stated:

Insulation shall be installed so that there is no air space between the top of the insulation and the floor.

Unacceptable work is not eligible for rebate, so a rebate now would give the home owner some compensation for the cost of needed repairs. The installer refused to accept any responsibility in this, but we will see what happens in review after the repairs.

In time, I devised a repair plan, posted for more than a year, and shared for comment with responsible parties, manufacturer Bonded Logic, Inc. and regulator Energy Trust Of Oregon. There was no thinking or standing up with me for the interest of the home owner.

This is the actual method of tying up crawl space batts that I had to work with. Batts were generally in pairs of matched 48" length, one 23" wide, the other somehow sawn 21" wide. The twine was fairly useful near to floor joists, and I left it in place. At about every 9" on average, in the slot between batts, I stapled up a loop of 17ga electric fence wire about 20" long, thus:

The battens typically were cut to 43" lengths. I used about 200 eight-foot lengths, costing $1.79 each. The lumber cost is significant.

Now consider how this might have been done, starting with new batts. I think each batt might be thrown up, upon a 2x3 or 2x4, to then be progressively secured higher-up, with wire and battens. The wires might be preset on other wire or lumber, adding to material cost but saving labor.

The same number of battens are needed whether or not there is benefit of prior twining. Lumber cost here remains about $400.

There is a nicer solution that has higher material cost, but would be superior overall:

Complete coverage with 3/8" CDX plywood sections costs about $15 for each eight-foot length of joist bay. Four eight-foot 1x2 battens in the same service would cost about $7. The lumber cost is doubled, but the isolation of insulation is a good deal, that should be mandatory. No insulation anywhere, not even on an attic floor, should be left raw, to be abused. Reduced labor costs might more than compensate for plywood cost. Where insulation is already hanging down but is not foul, this is a really good solution.

Home Performance Education For The Determined Or Advised Reader

The situation of waste found in this home had existed for nearly three years.

Enter then, myself, first for the attic work. I was discovered through new home owner membership in Angie's List. Already in Fall, 2011, I had been banished as a Trade Ally of Energy Trust of Oregon, and could not be found among the "players." Banishment for a year, but now seemingly forever, was for reporting to each customer the things I do, that are not done by those within the embrace of Energy Trust, contractors who brag upon the lies and malpractice of "Home Performance With Energy Star," HPwES.

The problems with HPwES begin with the basic lie in USA, that a blower door is the guide and measure of weatherization progress. As guide, in eight years of ever more-professional service, I have never seen a situation needing guidance of a blower door. As measure, achievable sealing rarely has value of more than $20 per year. A contractor who tells a home owner that blower door readings will guide and measure weatherization is a fool or a liar. Again and again, I challenge those contractors who submit to this scam and national scandal, to contradict my complaint. They do not and can not.

I have repaired many large energy bleeds not at all detectable by a blower door. Most attic floor pits, as with the generally-found chimney chase, have little effect on blower door readings. Where the goal is real or jiggered improvement of blower door readings, by hundreds of CFM50, correction of floor pits is not rewarded.

Even where they might affect blower door readings, bleeds are almost never found that way. The clean-shirted technician can not and will not be in the usual dark and dangerous attic while his blower door is operating, and therein is some revelation of the lying. It isn't just lying. It is costly ignorance. Workers will rarely take initiative to fix the things they might see and care about, of course unknown to the clean-shirted liar, then not in a contract. Buried problems usually have much higher opportunity cost, than any benefit from that which does the hiding. Rather, every job must have a graphic register of all the things fixed by the needed visual discovery, demonstrating demand of worker initiative, to entitle any public support.

It is good in the demonstration of alternative work in disdain of HPwES, that the involved contractor was and is, at the top tier of contractors managed by Energy Trust. This contractor has failed to acknowledge any errors. There was a well-intended confrontation about wrongful setting of an interior door in a blower door test and consequent mis-reporting of sealing results, and failure to accomplish the reported sealing. Later there was confrontation about useless crawl space insulation, where I believe the manufacturer and this contractor have cost liabilities. No such liabilities are yet admitted. I am backed up by Energy Trust, in offer of the deferred crawl space (floor) insulation rebate, now earned.

Among issues that could be seen and expressed, the home owner was very upset by ugly and useless "sealing", as characterized by this crude aerosol orange foaming about the exhaust duct of the kitchen microwave, in a kitchen cabinet.

The conditions of unacceptable sealing found, and their repair, can not be summed up in a few photos. For the detailed story of sealing, please download and study a large pdf album:

Real Sealing Fixes HPwES Sealing In An Oregon Attic

In this home, I infer incompetence at best, in the conduct and reporting of blower door and duct blaster measurements.

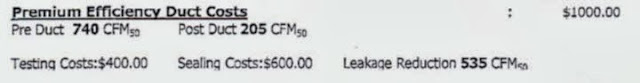

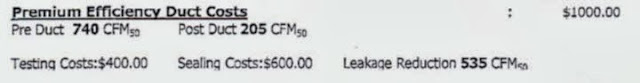

Where CFM50 = 7.5 * (Hole Size, sq in), total ducts hole size is 71 sq in., as with more than two 6" ducts (28 sq in each) fully detached. If workers found two duct sections detached, and reset them without comment, that is not duct sealing action of goop troops. It should not count. If ducts can fall down, then how could workers justify leaving the crawl space inaccessible after their departure? Leakage of 205 CFM50 is still huge, and should not be allowed. None of the steel ducts were found or left with required screws. Nearly all joints, now stiffened with goop, remained closed by dried-out ordinary duct tape. This was not duct sealing by some scientific process, and was not worthy of compensation. Most of the involved money should be reclaimed to compensate the home owner for the cost of my fully replacing the ducts, needfully and with courage, restoring access for extremely difficult work in the crawl space.

I don't believe sealing actions could have amounted to more than a few hundred CFM50. A 100 CFM50 reduction is closure of 13 sq in, a total equivalent hole four inches diameter or a gap 1/16" wide and 18 ft long. The great majority of reported reduction was from knowing fraud in devising a to-be-closed air handler room yet attic floor pit, with a gasketed new door. It is not allowed that an interior door may be closed in pre or post "Home Performance Testing." The door was a mystery to the home owner, perhaps to be closed for convenience.

This was my third run-in with this contractor, where I did the real sealing. In one, there were a car-bashed large hole in the garage wall, hidden behind a woodpile, and two closets with large leakage to outside controlled by closing doors; of course none found by blower door.

No one does better sealing of an attic floor or HVAC ducting than I do, with absolute disdain for fraud of Home Performance. I find problems as one must, digging down and dirty, by sight. I don't just reduce duct leakage. I methodically eliminate it, verifiable by sight as I go, and in method-sampling photos.

Here is discussion of my improvement of the crawlspace HVAC ducts in this home:

http://energyconservationhowto.blogspot.com/2013/11/more-hvac-circuitry-in-crawl-space.html

The ugly obstructions beginning at the access hole are gone! Repair of the cotton-batt insulation could only be done after removing the found HVAC ducts for recycling. Quite a pile. Hundreds of pounds of steel that had responded to every furnace cycle .

A system of handing out weatherization incentives that excludes my diligence is criminal. A customer who understands this, cares, and is willing to pay for fixing of messes, is very rare, and is a treasure to those who would learn through my experiences.