To assess achievements in any job, it is helpful to note starting conditions that had been coped-with for many years,

My 17' Little-Giant-like aluminum ladder in stepladder mode, reached this high to a ceiling 114.5" above the concrete floor.

A 3/8" plywood flimsy skirt about the "hole" was 16" high, far taller than surrounding R19 loose-fill insulation. Somehow from the top step of a step ladder, one had to place weight upon the wobbly skirt, to hurdle over tripping electric power cables and to land on a single 24" path to the furnace platform. Furnace filter changes and more demanded safe access.

All of the landing area is over house heated space and should have remained R38, undisturbed. R38, at R2.2 per inch, demands 18" insulation depth, not achieved anywhere. If insulation over 10% of heated space is only R8 and the remainder were actually R38, the effective R-value is as 1/(Reff + 3) = .1/11 + .9/41. Reff = 29. If the remainder is only R25, Reff is 21. In Metro Portland Oregon at Fall 2023, there is a $1.25 per sq ft rebate of cost paid for added attic floor insulation. Installation specifications: Existing insulation must be R-18 or less. Must insulate to R-38 or greater or the fill accessible cavity.

I would do further math to prove qualification at <R18, where space with no insulation, under the furnace and in general near roof eaves amply brings down the average.

The insulation space under the furnace platform is 10 1/4". I will build framing in new safe passage to the furnace that again is 10 1/4" tall. I want no trip-edges. Where the found loose-fill so-readily collapses to 3 1/2" depth, new insulation should be in the form of tough and resilient R25 fiberglass batts 24" x 48" parallel to the trusses, for total then of almost R38. Very importantly in this, all space with no insulation, must be filled. This might demand temporary jacking of the furnace off of the messy flooring, two heavily-nailed layers of 7/16" OSB.

The new, level plywood floor is non-tripping, although 19/32" plywood does flex some.

Get on now to the core purpose of this post, considering lessons learned with a unique attic ladder.

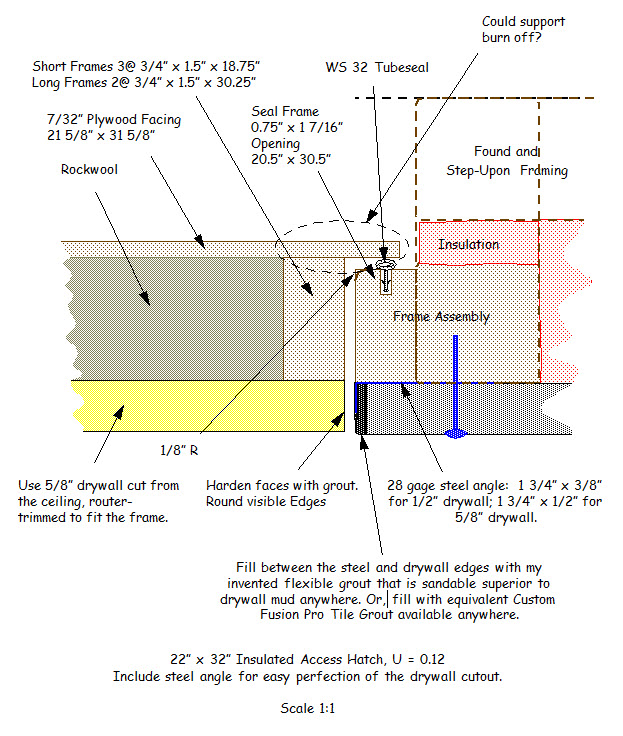

A fire-rated ladder must not be compromised by a gap about the ladder frame, only concealed by wood trim. This framing is trimless as seen in the full-scale drawing that follows.

Limit arm upper pivots are 5/16" x 2 1/2" lag screws embedded strongly in the ladder rough frame (well-strengthened truss bottom elements).

See that the ladder frame is tight against the perfectly-square rough frame. No shims. No gaps. With removal of a few screws, the ladder is fully removable, not bonded in place. At some future time, the ladder might be in the way of furnace replacement or removal.

The clear no-snags ladder opening with a 22" frame width will pass large bags of insulation now-needed. Know that no large garage like this could have other than 24" on-center framing. With truss framing, this is the best-possible accessibility. Be very grateful to have this last-of-its' -kind-on-Earth, wonderful attic ladder.

The deployed ladder steps are quite rigid, The two rails meet the floor equally with soft, gripping leveler legs.

The invoiced ladder cost is $419, now a bargain where inflation has doubled costs of weatherization since 2009.

See that the upper section of the ladder is highly customized. To have the Top Step I now demand for customer safety, I blocked the little step section, raised above the door, in a sturdy birch-plywood frame. The springs to-be-added can't be strong enough to have the heavier assembly slam-close as is foolishly and firmly a Fakro fire-rating feature. Fakro then will not offer a door latch that would reduce demands upon the springs.

I have been tasked then with invention of the latch, using good Central-European hardware purchased from one-time ladder manufacturer Calvert USA, in 2011. Calvert USA built excellent ladders in Maryland until 2016, including fire-rated ladders that did not cost extra.

This is the currently-offered Fakro LWF 54" ladder shown with 30" frame width. $805 at Home Depot. A large fraction of this cost is in individual FedEx or UPS shipments from an Illinois warehouse.

See much-steeper 66° fixed angle, and large springs obstructing the opening. The door linkage is at a tripping-point, no down-stability, ready to lift and slam with a nudge. The needed pretty handle is absurdly placed, with barely enough clearance for finger-grips.

Pay attention to a successful further evolution in nature of a tenting rest.

A screw protruding from the left stile engages the tenting rest slot. Stability of the tent is dependent on having the tent center of gravity well behind the tent pivot, the center of the step section hinge at left in this photo. Imagine a tenting rest serving any attic ladder, perhaps that drawn-on (darker) below the leveler leg here.

Study the dangerous factory-default deployment of this ladder at door angle 66°.

The better as-built installation is almost perfectly as drawn in the project bid. All installers of attic ladders should have such facility in planning. Surely architects demand this. Why should anyone want a ladder for its thoughtless cheapness?

Learn to follow the example of Swedish MidMade ladders in the location of lower pulls for the

balancing springs.

Want the upper and lower pivots of limit arms to be at the same elevation, as low as possible. See multiple drilled-in positions for lower pivots upon the door face. Each one-inch shift from the 60° position set, brings the door steeper by approximately 2°. Choose least-steep as the factory default.

Please know that I have successfully installed Fakro fire rated ladders of current production, with 60° default, springs resident on the door and pretty-good slam closure. I have wished these ladders could have door latches for more-firm sealing. Here is the installation of Fakro LWF 25/54 Model 869719, costing $770 in May 2022, and costing $855 in November 2023. Surely the customer now with the LWF 22/54 of 2009, has gotten a better deal.

Here is the stowed condition, showing spring leverage to pull fully closed. This works! Fakro should care to learn from my innovation, and has not.

Here see a door pull at the door opening end. There is no latch above. The door must self-close. See that installation requires facility with patching of drywall including fill of gaps to the steel edging that perfects frameless installation.

See more elements of the plastic Fakro Pull, as also a latch. I have had two of these from Fakro, not knowing what they are good for. The two long bosses at top in this view would need to be located very precisely by holes drilled in the opening (back) header of the ladder frame. The mating of the latch halves would be by strong slam, and release by very hard pull. I despair of installing this with sufficient accuracy, and don't trust long-term durability.

The slam closure is better with a smaller ladder 47" frame. Be convinced of invention, with this video of the 47" ladder: https://www.youtube.com/watch?v=YJ4pg_exdvs. With the easy-reach 47" ladder, there was no interest in tenting.

See a similar YouTube demonstration, year 2012, with a Calvert USA ladder and a ceiling nearly eleven feet up, in a home born as a warehouse of the 1905 Lewis & Clark Centennial Exhibition, in Northwest Portland, Oregon: https://www.youtube.com/watch?v=yBX8seprIO8.

Best fire-rated attic ladders are now wanted from manufacturer MidMade, in Sweden. None are on-offer, where imported by Conservation Technology, in Baltimore , MD. I am engaged in a campaign for change in this:

.JPG)