This is free sharing of discoveries in matters of methods, materials and policies for energy conservation in our homes. Discoveries are mainly in work I do with business Phillip Norman Attic Access, in metro Portland, Oregon. Please see my web site for this work, with my contact information: https://sites.google.com/site/phillipnormanatticaccess/ I am Phillip Norman , pjnorman@gmail.com, 1-503-255-4350.

Friday, August 30, 2019

Limits in Math With Compound Interest

The Key to a Sustainable Economy Is 5,000 Years Old

In my own words with faulty understanding, read:

Where investments are financed by individuals needing repayment in view of risks, opportunity cost and with depreciation of the investment through inflation, something must break. Compound interest does not work for terms beyond fifty years.

Catastrophic change is always with us. Within our productive lifetimes, we compensate within the limits of our strength and intelligence, if we are allowed.

Saturday, August 24, 2019

Mineral Wool Batt Exterior Wall Insulation of New Copenhagen Museum of Danish Resistance 1940-1945, Rebuild Opening 2020

All I could discover in the two days is within the water circle at center, this map URL .

Twelve hours past arrival, rested and oriented, I pursued a very active day within museum hours of about 10am to 5pm. Take a ten minute train ride from Central Station to Østerbro Station. Walk about Kastellet, and arrive at The Little Mermaid by 9am, This map URL

Continue about Kastellet, to Gefion Fountain, a bronze fountain completed in 1908, depicting Norse goddess Gefion plowing the sea with four oxen.. Admire the opal-hued clean water.

I didn't cross any of the bridges to the central island of Kastellet.

Soon at my left I passed Churchillparken , in part with a fence guarding a construction zone.

Learn this bit of history in tribute to Danish resistance of German occupation 1940 to 1945 :

The exhibition of The Museum of Danish Resistance remains closed due to a fire on April 28, 2013. The damage was so extensive that the building had to be demolished.

All museum objects and archives were saved. The damage was to the building only.

A new exhibition building will rise on the same spot. This new building is expected to be completed in Spring 2020.

See Rockwool stone wool batts placed as opportunity arises, to tight fill of the structure annulus.

This is a fast-moving scene of cylindrical brick-laying, with progressive insertion of mineral wool batts perhaps foot square, four feet long.

Rockwool Murbatts. What are they?

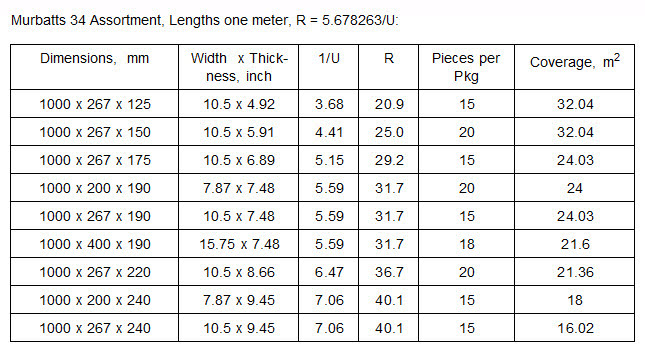

Murbatts are offered as Murbatts 32,34 and 37, where numbers are product thermal conductivity in units mW/m°K.

Here is an image of the Murbatts 37 datasheet, in English translation.

The many shapes and thicknesses offered are important for a spectrum of real-world insulation needs. Qualities wanted in the insulation of the building walls annulus include consistent dimensions and toughness in handling.

.

Translation from modern metric conversation, is first in dealing with units of measurement. I must convert my math and understanding of USA standards, to Danish practice with metric units. In the table above, for product Murbatts 34, see that thickness 150 mm (5.9 inch), has European 1/U = 5.51, and U = 0.18. Compare to required U of a wall, low value 0.2 or high value 0.4, in this EURIMA table.

https://www.eurima.org/u-values-in-europe/ I imagine the annulus in the photo is at least 150 mm. More likely, I think, 190 mm, 7.5", similar to the R30 thickest batts sold in USA.

Please study the presentation of Rockwool insulating value with this table for Flexibatts-37 and -34, for consistency with my USA Insulation Math and with method of conversion between USA R-value, and European U-value..

The units of European U-value are m²°K/W.

There are many fine details of European employment of Rockwool batts, needing instructive comparison to present USA home construction. Here is a cathedral ceiling.

Rockwool Poland documents some thoroughly-planned and intricate batt super-insulation, in this YouTube video with 1.7 million views.

https://www.youtube.com/watch?v=0OBdfQngh_M

From the Rockwool North America factory in Milton Ontario, or perhaps in Grand Forks British Columbia, I find a pretty-good spectrum of batt choices. These batt types and thicknesses are stocked by IDI, my insulation supplier in Tigard, Oregon. Pricing for me is included to show that Rockwool batts are less expensive than inferior fiberglass batts.

I think it is proper to compare insulation value as proportional to volume fully filled at claimed R-value, and with that volume reduced where observed batt thickness, is less than the space claimed to be filled. The minimum discounting of value is with wrong presumption that thinness alone is a problem. In fact, thin batts may have no value at all if outside air is free to circulate around and through the batt. Where a Rockwool batt claimed 3.5" is in fact 3.3", reduce batt volume by times 0.94. Where a fiberglass batt for a 3.5" space is only 3.0" thickness, reduce batt volume by times 0.86.

Look then at my year-2019 pricing at IDI, for fiberglass batts. Any manufacturer of fiberglass batts may be assumed, where manufacturers have colluded together to match and raise prices.

R19 kraft-faced $0.64 per sf

R23 kraft-faced $1.50 per sf

R15 unfaced $0.98 per sf

Bump these fiberglass prices up vs. Rockwool, by thinness ratio, 0.94/0.86, times 1.09. And know this is far too-fair to the fiberglass. Fiberglass batts allow far more air circulation through them and around ill-fitting edges. Kraft facing, usually without smart use of stapling tabs and with kraft crumpling, is disastrous to insulation value. Apply just the multiplier times 1.09.

At R15, fiberglass batts cost more by the ratio 1.09*0.98/0.75 = Times 1.42. Even the best fiberglass batts, R15, cost 42% more than Rockwool, or worse. Ordinary fiberglass batts may have no value at all.

Look back at sample prices I have paid for R15 unfaced fiberglass batts;

May, 2009 $20.61 for 67.81 sf, $0.30 per sf, $0.02 per R per sf

August, 2013 $20.61 for 67.81 sf, $0.30 per sf $0.02 per R per sf

June, 2014 $50.62 for 77.5 sf, $0.65 per sf $0.043 per R per sf

July, 2016 $58.24 for 112 sf, $0.52 per sf $0.05 per R per sf

April, 2018 $77.97 for 104 sf, $0.75 per sf $0.05 per R per sf

July, 2019, the not-exercised offer at $0.98 per sf. $0.065 per R per sf

I stopped buying fiberglass batts in 2018, equally because of poor thickness, and because of the accelerating cost. Who do fiberglass manufacturers think they are fooling? And where Owens Corning and Johns Manville offer decent mineral wool batts at Home Depot and Lowe's. know thickness and width offerings are very limited. Where Owens Corning offers smaller bags of ThermaFiber mineral wool, $13.93 for a 24.5 sf bag of R15-15 in July 2018, they do not capitalize on the excellent handling advantages and better pricing ($0.57 per sf vs. Rockwool $0.75). Other sizes, as for 24" framing, are not offered at either Home Depot, or Lowe's.

Hurrah, Rockwool!

I wish for reason to return to Copenhagen.

Copenhill, Copenhagen, Denmark

From afar Copenhill looks like a typical industrial plant with smoke billowing from its chimney. Get closer and you’ll spot adventurists traveling up and down the sloping roof of this shiny, metal-clad structure — and soon realize that Copenhill is an innovative and futuristic recreational park. There’s opportunities to ski, snowboard, sled, and hike. It’s even possible to scale the outside via the world’s highest climbing wall. All of this activity occurs on top of a waste-to-energy plant that helps to power thousands of city homes — part of a mission to turn Copenhagen into a carbon-neutral capital, and to offer alpine sports in a mountainless country.

Thursday, August 8, 2019

Clip-In LED Edge Lights for Elimination of Light Cans

This is the attic situation resolved. A home has bulky insulation batts generally of no value, out of contact with ceiling drywall. I am only allowed to tuck-in the batts, and that doesn't work at the can lights.

I can do a lot better in the batt tucks, where the Commercial Electric kit is swapped-in.

Here are competing edge lights at Home Depot that are nicely sized to replace a 6" can. Both have the Home Depot notion we have many differing preferences for color temperature of the edge-tape diodes. I believe the 3000°K setting is best, and I believe blue coloring is always - - ugly .

Here are similar offerings at Lowe's stores that would serve 4" and 6" can elimination.

Two more from Lowe's:

Ridiculousness of large ceiling cuts for edge lights is seen here in the extreme. The 4" light requires a 6 1/4" ceiling cut. The 6" light requires a 7 5/8" ceiling cut.

Here is a Lithonia 1600 lumens edge light requiring a cutout 8 1/4" dia., sold at Home Depot. These giant holes are not related to any can size where there might be an existing hole then excused. Surveying cans for sale in Home Depot and Lowe's stores on 8/11/2019, I found hole prescribed sizes of 6" mainly, and in addition 5 1/2" for 5" cans and 4 1/4" for 4" cans. One will find clip-in edge lights that replace 6" and 4" cans, but not 5" cans. Replacements for 7" cans? Maybe.

No clip-in edge light I have found so far, apologizes for the excess ceiling cut. None names the opportunity as can elimination.

Saturday, March 23, 2019

Working With Mineral Wool Batt Insulation

In two jobs of attic floor insulation, and again in the completion of a kitchen remodel in my home, I have made a thorough try of mineral wool batt insulation by Roxul, company now called Rockwool, and by Owens Corning, product called Thermafiber. One experience is summarized in this post. All are collected in blog posts search; Label: Mineral Wool Batts. I am late in preferring mineral wool batts to fiberglass because I work mainly in attics and crawl spaces, where mineral wool has seemed difficult and extravagant. In fact, real momentum in the deployment of mineral wool batts is since the 2013 acquisition of Thermafiber by Owens Corning.

Second Home With Attic Floor Mineral Wool Batt Insulation

This 1918 home has excellent 4 ft wide roof eaves sheltering windows and walls and giving an 18" tall attic perimeter. R49 attic floor insulation out to exterior walls is uniquely possible. Good elevation over exterior walls is an asset to running modern wiring down the exterior walls.

The attic has been barely accessible, dark and dangerous. Despite hostility, the large attic has household items preserved in storage. There is appearance of thick insulation, but many defects reduce effective value to a very poor R5.

After the attic floor has been framed to support an attic ladder, set a barricade to contain dust and plaster chunks of new attic access cuts conveniently aligned with a stairwell.

The found 2x6 attic floor joists will be strengthened to 2x12, with box beam methods. Build and install a ladder rough opening frame, using select 2x12 lumber. Bahco hand saw cuts through lath and plaster are guided true against the RO frame that is well fit to the ladder frame.

11 1/4" plywood rips serve as box beam webs. Beam top elements are longest-possible 2x4. Everywhere the found loose-fill mineral wool is only 2" deep; found batts draped over that had no value and has been in my way. I am happy to reset all found fiberglass batts within the box beams, packed intimately and with much elimination of framing thermal shorts. Found fiberglass batts are progressively shaken free of dust and roof debris upon sheets and into 55 gallon drum liners, piled and rationed as base fill within variable spaces below the level of flooring 2x4 nailers.

I started out knowing only of Rockwool batts, available as R15 and R30, and in unrated 2" thickness. Cut batts 23" wide, to lengths (shorter dimension) accurately fitting framing spaces, using a long commercial bread knife.

18" tall perimeter vertical framing is continuation of exterior walls below, always with closure of cavities in the attic floor (not balloon framing). Hard-covered insulation is 12" thick. I am able to go anywhere in the careful placement of wiring, lighting and new fans, then to be capped with a maximum depth of insulation.

In a final, nicely-accessible zone 54” wide at the North end of the attic, show learned exemplary use of mineral wool batt insulation. I ran out of found wimpy fiberglass for the base layer. At LHS, 2” of loose-fill mineral wool gives intimate bedding on lath and plaster roughness. Over that add R11 kraft-faced batts and R8 mineral wool batts, a total of R21. Crossing Thermafiber R30 batts 24” by 48”, 6” thick, bring the total in 11.5” depth, to true R49.

Over the master bath drywall at RHS, there was no found loose fill. begin with R11 unfaced batts for 1 1/2” fill to tops of on-flat 2x4s found.

Make note of more insulation stack-ups in 2x12 box beam caviies, exemplary of the use of mineral wool batt insulation, rarely disposing found insulation.

This is typical. I gave up on the use of housewrap strips after nearly hurting myself with kick of a circular saw dividing the plastic housewrap roll. Never again!

Note batt stack-up nearing attic completion, with little remaining found-fiberglass and no raised flooring. Total about R52. What else might one do to achieve serviceable insulation greater than R49? Top-layer R30 batts 24” x 48” are placed, and may be retrieved, from the flooring edge. A covered bath fan and lights will need service someday, then not destroying insulation. The stackup will vary with what materials are at hand, and with needs to fit objects buried.

This is the Fakro LTK 25/47 attic ladder leading to the completed attic now very energy-efficient, and useful.

Summarize the placement of 1/2" CDX plywood, 22.5 sheets reassembled from 24" rips.

Summarize the attic features.

Summarize the best energy-savings opportunity, closure of attic floor pits. I employ a concept of "equivalent bare area", to collect the savings value of closing air-tight and insulating over the pits.

Here are summary photos of the floor pits as found, and as closed. The opportunities are mostly associated with drop ceilings of closets, now closed or filled full.

Looking Northeast from atop the attic ladder, see an expanse of flat and level flooring. There is easy access to fans and to wiring that is concentrated at the periphery.

From atop the attic ladder, look Southwest past the safety pole, and see all stored items, now easily accessible.

The full story of work in this attic may be seen in job photo album:

Kabeiseman Attic, June 2018

The story of happiness in finesse work with mineral wool batts, mainly Rockwool now, will go on and on as I continue my work as an exemplary weatherization contractor, age 75 and growing, working always by myself for the experience-to-share. Here are more job albums with employment of mineral wool batts (stone wool):

Coleman Garage Attic, April 2018

Varma Attic, June 2019

Crockett Garage Attic, June 2019

Worthington Attics, January, 2020

I am grateful always for readers, and watch for progress at StatCounter. In this January 2020 update of my post I am inspired by a reader in Japan. I am especially grateful for reader response in comments to a blog post. I will respond to post comments, and I will respond to direct email contact:

pjnorman@gmail.com