(Gone! The subject of this post was pulled down in 2016, replaced by a Pilot II study.)

Perhaps I am responsible for this. I discover the amendment only in August 2023 upon seeing that a reader in Tualatin Oregon would have been frustrated by the missing link.)

The newer report now at the link below, produced by an outside consultancy, Evergreen Economics and SBW Consulting, Inc.. Methods tested remain impractical and inapplicable to an existing home, thus dumb and irrelevant in my judgement. Please scroll to the bottom of this post to find review of this Pilot II report. Still want use of sealing grout, and intelligent gaskets offered by Resource Conservation Technology. Want sealing in many existing homes to involve room-by-room

wall drywall demolition and replacement, along with wiring and plumbing modernization.

Final Evaluation Report - New Homes Air Sealing Pilot II

Photo Caption:

Figure 1. Photograph of sill sealer (pink band at top of wall) installed on the top plate prior to drywall installation (courtesy of Fluid Market Strategies; Manclark, 2013).

I judge that pink material in this photo is OWENS CORNING FoamSealR Sill Gasket - 3 1/2 inch x 50 feet. x 1/4 inch, roll polyethylene foam, sold in Home Depot stores and elsewhere. Thickness might be as little as 3/16" in a less-available roll 4" wide and 86' long. Either is too thick, too wide and too incompressible, not imagined for this application.

I found edges of this material in November 2013, in a new Hillsboro, Oregon DR Horton home, both sides of each interior-wall header, upon installing a needed attic ladder. I couldn't reach out to exterior walls, those shown in the photo. I infer that all walls were treated, at top header only. The report of the air sealing test admits unhappiness of involved drywall installers. Drywall panels are placed with sliding action that tends to grab and roll the strips, and a deservedly-angry installer will rip out the damnation. The non-flat panel edges show, and that can't be hidden with ordinary mudding. There are better ways, of course.

The better ways to seal wall headers in wall construction include use of building gaskets by Conservation Technology, Baltimore, MD .

Here is copied descriptive text by Conservation Technology:

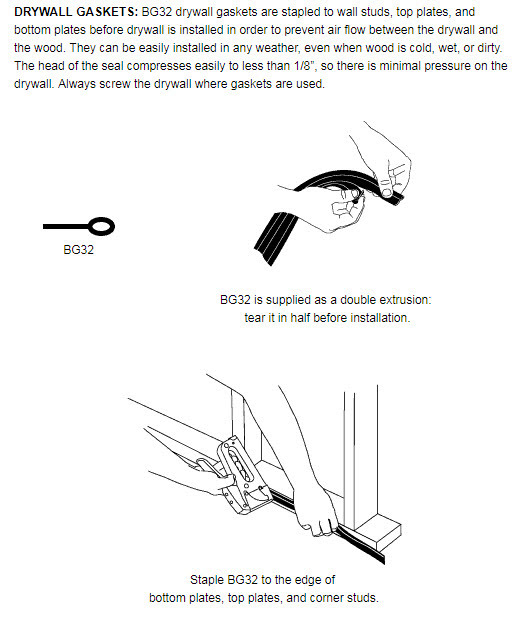

DRYWALL GASKETS: BG32 drywall gaskets are stapled to wall studs, top plates, and bottom plates before drywall is installed in order to prevent air flow between the drywall and the wood. They can be easily installed in any weather, even when wood is cold, wet, or dirty. The head of the seal compresses easily to less than 1/8”, so there is minimal pressure on the drywall. Always screw the drywall where gaskets are used.

Please know that Conservation Technology also offers best rim joist and sill plate gaskets:

At the associated Picasa web album , please find photo excerpts of the Conservation Technology products, and of exterior-wall header sealing achieved without gaskets where Swedish Tenoarm air/ vapor barrier material is employed. Buy the Tenoarm too from Conservation Technology.

Please see discussion of wall header sealing as weatherization retrofit, in the attic floor, at posts including this:

Sealing Wall Headers

There find report that where my flexible grout is not commercially available, I offer free samples, and find that Custom tile grout is chemically very similar, and is available anywhere. Learn that spray foam is always inferior.

Silliness of the test accused? That a blower door measures effectiveness , and that a better sealing means was not found. Anything that requires a bribe for delivery, is wrong. No one should mind working with BG32 gaskets. They cost no more than the roll foam. Close to board ends, they do not affect drywall fit-up, shape and mudding. Wall header sealing must be made mandatory. The gaskets are an easier way, and can be delivered at outside walls not accessible from the attic. We don't need to retool, and do more stupid play with blower doors. Sealing will stop action of attic floor pits, far more than it affects exchange of outside air. Testing might instead consider the thermodynamics of interior wall flooding through wall header gaps of variable size. "Experiments" should never be conducted where conditions are not controlled, and where instruments are insensitive to results.

This goes beyond silliness, to deceit. There is a budget and strong intent , to continue the madness of the Energy Trust/ DR Horton Homes program despite now knowing better, where all involved are aware of my criticism.

It isn't only that wasteful experiments take place employing inappropriate gaskets. High-end new homes are being built in Oregon, where foolish gasketing is done as taught good practice. I found this gasket scrap under insulation on the floor of a new home attic. It was ripped from stapling as a probably-angry act. If by drywallers as is likely, no other sealing was offered in its place. This is not a less-expensive way to seal wall headers. Please, let us commit to sealing in all new homes and tear-down remodels, using good gaskets from Conservation Technology.

Working in customer existing-home attics, I have not had opportunity of wall header sealing other than as forcing of flexible grout from the attic, upon interior walls. My practice in this is detailed in the advocacy web site, Plaster Repair How To, search Label: Wall Header Sealing . Gaps found have sometimes been huge, up to 1/4" and not possible of sealing with any practical gasket. I found such gaps even in my own home, well built by my uncle and oldest brother. Here are drippings from wet grout that penetrated stuffed-in fiberglass insulation, revealed in demolition for a kitchen remodel. I will always believe that surest sealing of headers is from the attic, before a careful manual placement of batt insulation.

Although I can do right again in my attic, at last buy a coil of BG32 gasket from Conservation Technology.

A 100 ft coil serving 100 lineal feet of wall at both top and bottom, is inexpensive. This coil cost me $40, plus $23.25 shipping. A local wholesaler could have sold the coil for $50. This is fully affordable and must be mandatory where cost is repaid with savings in about one year.

The gasket material is tough EPDM. Know that EPDM has 5 to 10 year shelf life and will remain serviceable indefinitely while not disturbed.

Split lengths for two gaskets, with scissors.

Attach with staples. Here on an interior wall, I will back up gap filling in the attic. See that I have sealed the existing drywall of the opposing room, with flexible grout. I have stuffed annuli around electrical wires, with Rockwool scraps.

On an exterior wall stuffed with insulation and with windows and doors, value of the BG32 gasket is uncertain. I didn't apply it before placing drywall to the right of this door. At 25 cents per ft, top-only, the cost is trivial. I got more placement practice, learning that 3/8" staples are needed.

Final Evaluation Report - New Homes Air Sealing Pilot II

Photo Caption:

Figure 1. Photograph of sill sealer (pink band at top of wall) installed on the top plate prior to drywall installation (courtesy of Fluid Market Strategies; Manclark, 2013).

I judge that pink material in this photo is OWENS CORNING FoamSealR Sill Gasket - 3 1/2 inch x 50 feet. x 1/4 inch, roll polyethylene foam, sold in Home Depot stores and elsewhere. Thickness might be as little as 3/16" in a less-available roll 4" wide and 86' long. Either is too thick, too wide and too incompressible, not imagined for this application.

I found edges of this material in November 2013, in a new Hillsboro, Oregon DR Horton home, both sides of each interior-wall header, upon installing a needed attic ladder. I couldn't reach out to exterior walls, those shown in the photo. I infer that all walls were treated, at top header only. The report of the air sealing test admits unhappiness of involved drywall installers. Drywall panels are placed with sliding action that tends to grab and roll the strips, and a deservedly-angry installer will rip out the damnation. The non-flat panel edges show, and that can't be hidden with ordinary mudding. There are better ways, of course.

The better ways to seal wall headers in wall construction include use of building gaskets by Conservation Technology, Baltimore, MD .

Here is copied descriptive text by Conservation Technology:

DRYWALL GASKETS: BG32 drywall gaskets are stapled to wall studs, top plates, and bottom plates before drywall is installed in order to prevent air flow between the drywall and the wood. They can be easily installed in any weather, even when wood is cold, wet, or dirty. The head of the seal compresses easily to less than 1/8”, so there is minimal pressure on the drywall. Always screw the drywall where gaskets are used.

Please know that Conservation Technology also offers best rim joist and sill plate gaskets:

At the associated Picasa web album , please find photo excerpts of the Conservation Technology products, and of exterior-wall header sealing achieved without gaskets where Swedish Tenoarm air/ vapor barrier material is employed. Buy the Tenoarm too from Conservation Technology.

Please see discussion of wall header sealing as weatherization retrofit, in the attic floor, at posts including this:

Sealing Wall Headers

There find report that where my flexible grout is not commercially available, I offer free samples, and find that Custom tile grout is chemically very similar, and is available anywhere. Learn that spray foam is always inferior.

Silliness of the test accused? That a blower door measures effectiveness , and that a better sealing means was not found. Anything that requires a bribe for delivery, is wrong. No one should mind working with BG32 gaskets. They cost no more than the roll foam. Close to board ends, they do not affect drywall fit-up, shape and mudding. Wall header sealing must be made mandatory. The gaskets are an easier way, and can be delivered at outside walls not accessible from the attic. We don't need to retool, and do more stupid play with blower doors. Sealing will stop action of attic floor pits, far more than it affects exchange of outside air. Testing might instead consider the thermodynamics of interior wall flooding through wall header gaps of variable size. "Experiments" should never be conducted where conditions are not controlled, and where instruments are insensitive to results.

This goes beyond silliness, to deceit. There is a budget and strong intent , to continue the madness of the Energy Trust/ DR Horton Homes program despite now knowing better, where all involved are aware of my criticism.

It isn't only that wasteful experiments take place employing inappropriate gaskets. High-end new homes are being built in Oregon, where foolish gasketing is done as taught good practice. I found this gasket scrap under insulation on the floor of a new home attic. It was ripped from stapling as a probably-angry act. If by drywallers as is likely, no other sealing was offered in its place. This is not a less-expensive way to seal wall headers. Please, let us commit to sealing in all new homes and tear-down remodels, using good gaskets from Conservation Technology.

Working in customer existing-home attics, I have not had opportunity of wall header sealing other than as forcing of flexible grout from the attic, upon interior walls. My practice in this is detailed in the advocacy web site, Plaster Repair How To, search Label: Wall Header Sealing . Gaps found have sometimes been huge, up to 1/4" and not possible of sealing with any practical gasket. I found such gaps even in my own home, well built by my uncle and oldest brother. Here are drippings from wet grout that penetrated stuffed-in fiberglass insulation, revealed in demolition for a kitchen remodel. I will always believe that surest sealing of headers is from the attic, before a careful manual placement of batt insulation.

Although I can do right again in my attic, at last buy a coil of BG32 gasket from Conservation Technology.

A 100 ft coil serving 100 lineal feet of wall at both top and bottom, is inexpensive. This coil cost me $40, plus $23.25 shipping. A local wholesaler could have sold the coil for $50. This is fully affordable and must be mandatory where cost is repaid with savings in about one year.

The gasket material is tough EPDM. Know that EPDM has 5 to 10 year shelf life and will remain serviceable indefinitely while not disturbed.

Split lengths for two gaskets, with scissors.

Attach with staples. Here on an interior wall, I will back up gap filling in the attic. See that I have sealed the existing drywall of the opposing room, with flexible grout. I have stuffed annuli around electrical wires, with Rockwool scraps.

On an exterior wall stuffed with insulation and with windows and doors, value of the BG32 gasket is uncertain. I didn't apply it before placing drywall to the right of this door. At 25 cents per ft, top-only, the cost is trivial. I got more placement practice, learning that 3/8" staples are needed.

The Evergreen Economics and SBW Consulting, Inc. Pilot II Report, April 21, 2016

Once again, it was thought wrongly that sealing effects could be observed with meaningful precision in blower door testing, to discriminate between homes sealed and not sealed. Delta values were in the desired direction, but by only one standard deviation. These were not at all a test of insulation wind washing.

Tested Knauf Eco Seal was a by-gun goop-gasket application failure especially if applied with ambient below 60°F.

Owens Corning Energy Complete is a messy and unreliable two-component foam application.

For each product, half of homes in a study were sealed and half were not; mean for those not sealed.

Recommendation at report page 15, as wished:

Given the results, we do not recommend that the New Homes program move forward with the whole home and attic sealing measures tested in this pilot.

Energy Trust expensively justifies doing nothing with home air sealing. No incentives are offered.

No comments:

Post a Comment